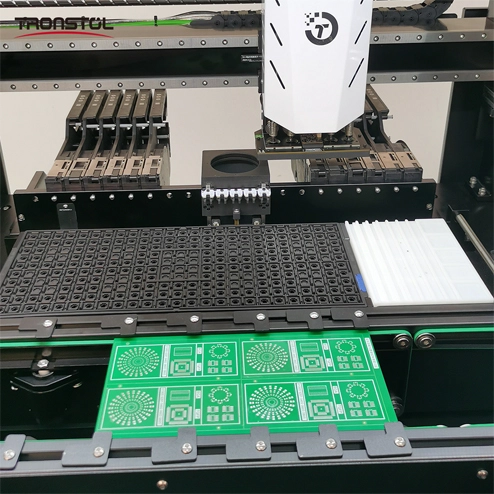

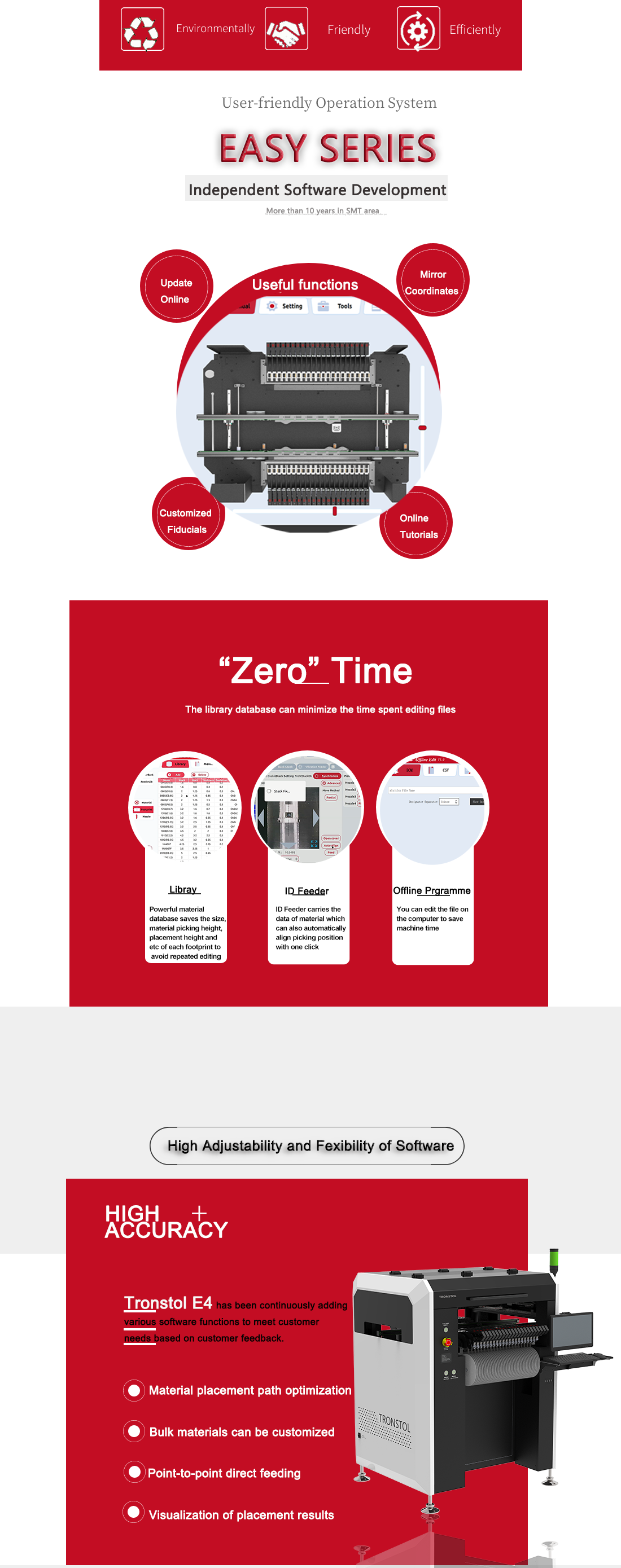

TronStol E4 is based on an integrated welded steel frame,equipped with dual-side Y-axis drives. The design of servo motors, ground ball screws with an encoder feedback closed-loop to achieve high-precision motion control. Compared to single-side Y-axis open-loop systems,our system offers significantly higher repeatable positioning accuracy.The vision system uses four CCD laser flying cameras and one Mark camera to achieve on-the-fly imaging, high-speed positioning, and high-precision recognition.It has 4 heads,with the auto nozzle changer,8 different models of nozzles can be used together.The self-developed software system has the function of "Libray",when there is enough material database, you can mount new PCB directly after testing without editing the new file.

86-571-26265158

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt